Proven Strategies for Warehouse Optimization

Maximizing the use of vertical space is one of the most effective ways to increase storage capacity and efficiency in your warehouse. Whether you’re working with traditional storage solutions, space-transforming additions, or cutting-edge automated systems, there’s an ideal approach to help you make the most of your warehouse height. Here, we’ll cover some of the best strategies for using vertical space, from pallet racking to advanced automated solutions.

Traditional Storage Solutions

Traditional storage systems like pallet racking and industrial shelving are staples of any well-designed warehouse. They are versatile, sturdy, and ideal for storing items of all shapes and sizes.

- Racking Systems: Utilizing the vertical dimension effectively means stacking higher. Installing taller pallet racking systems can provide more levels for storage, especially if you have the equipment to reach higher safely. Consider optimizing your existing pallet racking by adding more levels, and if need be, changing out your uprights.

- Industrial Shelving: Industrial shelving can also help utilize vertical space by offering multiple tiers of storage. By extending these shelves vertically, you make use of the often underutilized overhead space, increasing storage density without taking up additional floor area. Two-level and three-level high configurations are possible depending on load and seismic specifications.

Remember, when expanding traditional storage systems upwards, always ensure the shelving or racks are designed for additional levels of storage and are securely anchored. In order to leverage storage at greater heights, your team must be equipped with the appropriate material handling equipment for access.

Space Transformation Products

Another approach to vertical optimization is adding space transformation products to your warehouse space. These additions create a second or third level without expanding your building’s footprint, adding value to the vertical space that otherwise goes unused.

- Mezzanines: A mezzanine is a great way to create an additional layer within your warehouse for storage, office space, or even workspace for light assembly. It can serve as a dedicated area for storing less frequently accessed inventory, freeing up valuable floor space for high-demand operations.

- Modular Offices: Modular offices can be placed on a mezzanine to take advantage of height and clear out valuable floor area. This allows for a versatile work area that doesn’t encroach on operational space—ideal for supervisors or administrative tasks within the warehouse.

Using mezzanines or modular offices can effectively double the functional area without the need for new construction, keeping both costs and interruptions minimal.

Automated Storage Systems

Automated storage systems offer the most efficient use of vertical space by leveraging technology to improve access, safety, and storage density. Systems like Vertical Lift Modules (VLMs), Pallet Shuttle Systems, and Mobile Racking can take your warehouse operations to the next level.

- Vertical Lift Modules (VLMs): VLMs are perfect for managing small to medium items, automatically retrieving products stored vertically in trays. This system not only optimizes space by allowing for storage up to the ceiling but also increases picking speed and reduces labor efforts, making them an ideal solution for high-value or high-turnover inventory.

- Pallet Shuttle Systems: A pallet shuttle system like the Automha Pallet Runner can also be a great solution for vertical space. Considering this system does not have any pitch required to function, pallets can be stored at greater depths and heights. The key to the system are the automated shuttles that move pallets as needed, reducing the need for forklifts to maneuver at elevated levels.

- Mobile Racking: Mobile racking systems are an excellent way to further utilize vertical and horizontal space. These systems are mounted on motorized bases that move along rails, allowing aisles to open and close as needed. This maximizes floor space while still making use of the full height of the warehouse, making it perfect for environments where both flexibility and efficient vertical use are key.

General Tips for Maximizing Vertical Warehouse Space

If you’re not quite ready for a complete system upgrade, there are still simple strategies to make better use of vertical space in your warehouse:

- Install Stackable Bins and Containers: Use stackable bins and containers to organize smaller items on tall shelving. This ensures efficient use of vertical space while keeping products accessible and organized.

- Evaluate Clearance Heights: Make sure your storage systems are utilizing the full height of your building. Often, additional clearance above current racking or shelving can be converted into usable storage by adding more levels or choosing taller shelving.

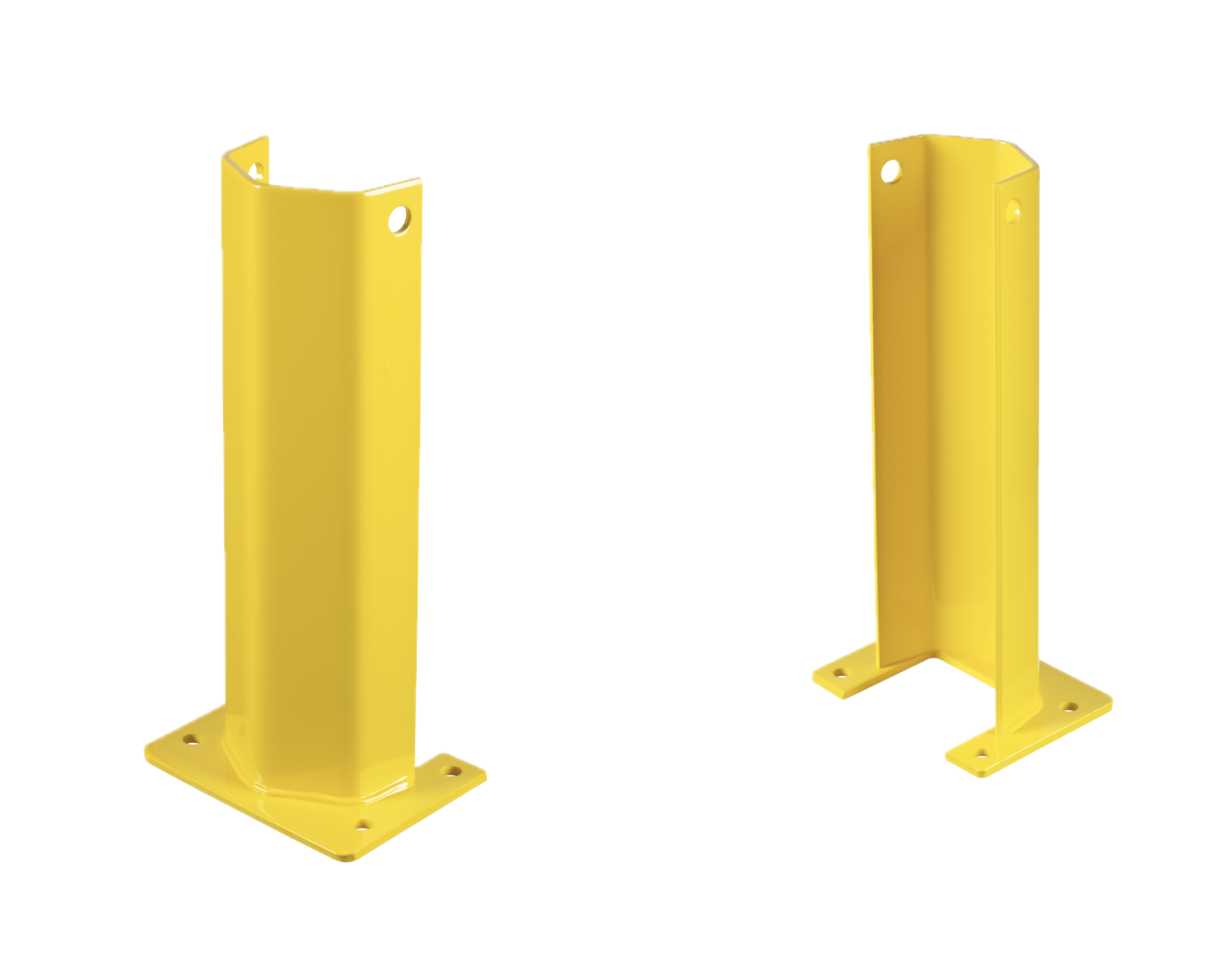

- Consider Vertical Safety: Safety is key when expanding upwards. You should ensure that your foundation and storage equipment material itself is suitable before adding additional loads.

- Label Clearly: If you’re storing items higher, clear and visible labeling becomes even more critical to ensure workers know where items are located without needing to search unnecessarily.

Bringing It All Together

By leveraging a combination of traditional storage solutions, transformative space options like mezzanines, and the power of automation, you can significantly boost the efficiency of your warehouse space. A well-organized, vertical storage strategy doesn’t just maximize space—it transforms your operations, increases productivity, and ultimately contributes to a safer, more efficient warehouse.

Interested in optimizing your vertical space? Contact us today to discuss the best solutions for your warehouse.

Frequently Asked Questions (FAQ)

Q: How to use vertical space for storage?

A: To use vertical space effectively, evaluate your ceiling height, utilize taller pallet racking or industrial shelving, and consider mezzanines or automated systems like Vertical Lift Modules (VLMs) to maximize efficiency. Ensure proper safety measures are in place, such as guard rails and secure anchoring, and make sure your material is rated for the loads you are putting on it.

Q: What are the benefits of using vertical space for storage?

A: Utilizing vertical space helps maximize warehouse storage capacity without expanding your warehouse footprint. This can lead to increased operational efficiency, reduced clutter, better safety, and cost savings by avoiding the need for new construction.

Q: What safety measures should be taken when utilizing vertical storage?

A: Safety is critical when using vertical storage. Ensure that all racks and shelving are properly anchored, install guard rails where necessary, and train employees on how to safely access higher storage levels. Additionally, using equipment like forklifts and lifts designed for vertical access can help minimize risks.

Q: How can I start optimizing my warehouse for vertical storage?

A: Start by assessing your current storage setup and ceiling height. Identify areas where additional levels could be added, and consider which type of storage solution (traditional, mezzanine, or automated) best fits your needs. Partnering with a storage solutions provider, like Prestige, can help you create a tailored plan that optimizes your vertical space effectively.