Pallet Racking Systems

Maximizing Warehouse Space with Pallet Racking Systems

Effective warehouse storage is essential for operational success. Pallet racking systems represent the foundation of traditional warehouse storage, enabling businesses to organize and access inventory with precision and speed. These systems have been refined through years of industry experience, forming the backbone of successful warehouse operations. While automation technologies continue to evolve, well-designed pallet racking systems remain vital for optimizing warehouse space and throughput. As the Southeast’s premier Steel King distributor, Prestige provides high-quality pallet racking solutions designed to maximize your warehouse’s potential and drive operational efficiency.

Key Components of Pallet Racking Systems

Pallet racking systems offer a structured approach to warehouse storage, enabling businesses to store inventory efficiently while maintaining accessibility and safety. Prestige offers a comprehensive range of pallet racking solutions that can be tailored to meet your operation’s specific requirements:

- Selective Pallet Racking

Ideal for warehouses requiring direct access to every pallet. Offers maximum flexibility with adjustable beam levels for varying pallet sizes, easy scalability for growing inventory, and optimal configuration for facilities managing a wide mix of products.

- Drive-In & Drive-Thru Racking

Forklifts can drive directly into the racking lanes. Drive-In uses LIFO inventory rotation, while Drive-Thru supports FIFO. A high-density storage system designed for storing large volumes of a single SKU with excellent space utilization and durable, heavy-duty construction.

- Push-Back Racking

Stores pallets up to five deep using carts on inclined rails. Supports LIFO inventory rotation, improves selectivity compared to Drive-In, and minimizes forklift travel by automatically advancing pallets to the front. A high-density solution for operations balancing accessibility and storage volume.

- Pallet Flow Racking

Also called gravity flow racking. Utilizes rollers for automatic pallet movement from load to pick face. Ensures FIFO rotation, streamlines picking in high-volume environments, and reduces labor by minimizing forklift movement. Ideal for high-density, fast-moving inventory storage.

- Mobile Pallet Racking

Mounts pallet racking onto movable carriages that slide open and closed on tracks. Eliminates fixed aisles to maximize space utilization, making it a high-density option well-suited for cold storage, archival storage, or any facility where floor space is at a premium.

Unlock the potential of your storage space – Contact our team for a free consultation!

Pallet Rack Construction Types

The construction type of your pallet rack shelving impacts durability, flexibility, and suitability for different warehouse environments. Prestige offers two primary options to meet a range of operational demands:

- Roll-Form Pallet Rack

A cost-effective, boltless system that’s quick to assemble and easy to adjust. Lightweight components make it ideal for standard warehouse operations requiring frequent reconfiguration and lighter to moderate load capacities.

- Structural Pallet Rack

Engineered for maximum strength and durability using hot-rolled steel and bolted connections. Designed to withstand heavy loads and repeated forklift impact, making it the preferred choice for high-abuse environments and long-term performance.

Roll-Form Rack

Structural Channel Rack

The Advantages of Pallet Racking Systems

Pallet racking systems continue to offer significant advantages for warehouses of all sizes. These strategic storage solutions balance accessibility, space utilization, and operational efficiency, which many businesses find necessary. Some key benefits that make pallet racking a compelling choice for optimizing warehouse operations include:

- Space Optimization: Pallet racking maximizes vertical storage space, increasing storage capacity without expanding your warehouse footprint.

- Inventory Organization: Systematic storage arrangements improve inventory management, reduce picking errors, and enhance operational efficiency.

- Accessibility: Properly designed racking systems ensure quick access to stored items, reducing retrieval time and improving throughput.

- Flexibility: Racking components can be reconfigured or expanded to accommodate changing inventory needs and warehouse layouts.

- Safety: Professional racking systems, when properly installed and maintained, provide safe and stable storage for heavy and valuable inventory.

Challenges & Considerations

While pallet racking systems offer numerous benefits, effective implementation requires addressing several key considerations:

- Layout Planning: Proper layout design is critical for maximizing space utilization while ensuring safe and efficient material handling.

- Weight Capacity: Understanding load capacities is important for safety and preventing structural failures in racking systems.

- Forklift Compatibility: Racking systems must be designed with appropriate aisle widths and clearances for your material handling equipment.

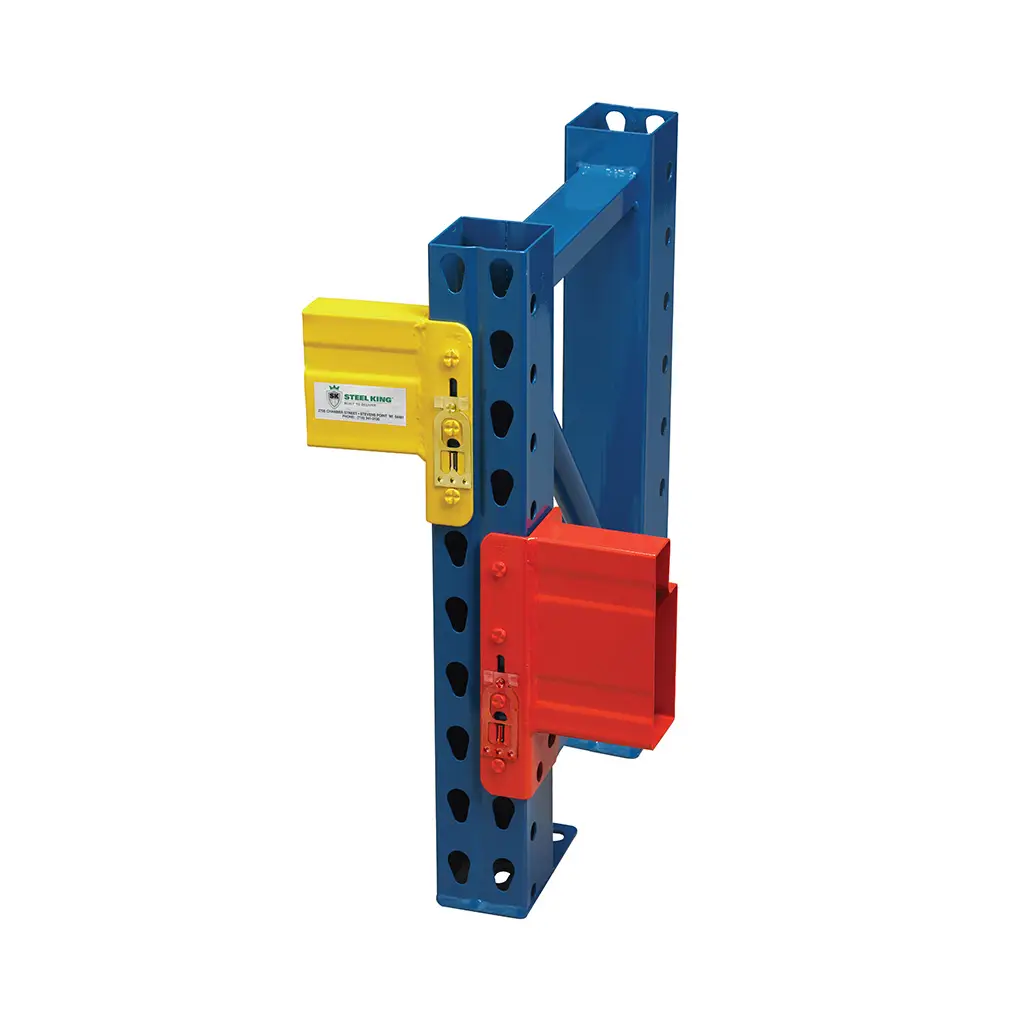

- Safety Requirements: Proper safety equipment including post protectors, guard rails, and wire mesh backing must be incorporated into the racking system design.

Behind the Rack: The Team Driving Your Storage Success

At Prestige, we are passionate about revolutionizing warehouse storage and material handling solutions. Since 1970, we have been at the forefront of providing innovative, efficient, and customized pallet racking solutions for businesses across various industries.

Our team of experts brings decades of experience in warehouse storage systems, space transformation, and automated integration. Whether you’re expanding, reorganizing, or upgrading your storage system, Prestige offers the expertise and products to enhance your warehouse efficiency.

Let us help you unlock the full potential of your warehouse space with pallet racking systems designed specifically for your operational requirements.

FAQ

Commonly Asked Questions

What is the most efficient pallet racking system for my warehouse?

The most efficient pallet racking system depends on your specific operational needs, inventory characteristics, and space constraints. Selective pallet racking offers direct access to every pallet and is ideal for warehouses with diverse SKUs and frequent access requirements. High-density systems like drive-in racking maximize storage capacity but limit immediate pallet accessibility. Push-back and pallet flow systems balance density with accessibility. Our experts can evaluate your facility and inventory profile to recommend the optimal racking configuration that aligns with your operational goals and space limitations.

What safety equipment is required for pallet racking?

Essential safety features for pallet racking include post protectors to shield uprights from forklift impact, load stops to prevent pallets from being pushed too far back and falling off the racking, wire mesh backing to prevent items from falling, and beam safety locks to secure horizontal components. Our team can recommend and implement the right safety solutions to protect both your employees and your investment.

Can pallet racking integrate with other warehouse equipment and systems?

Yes, pallet racking systems readily integrate with various warehouse equipment and technologies. They can be designed to work with forklifts, pallet jacks, and order pickers. More advanced integration includes compatibility with automated storage and retrieval systems (AS/RS), Pallet Shuttle Systems, conveyor systems, and more. When planning a comprehensive warehouse solution, our experts consider how racking systems will interact with existing or planned equipment to create a cohesive and efficient operational environment.