Vertical Lift Modules

SUPERCHARGE YOUR STORAGE

Vertical Lift Modules (VLMs)

The Modula Vertical Lift Module (VLM) offers exceptional space utilization and streamlined picking for facilities that need to make the most of their footprint. Engineered for both efficiency and accuracy, the Modula VLM simplifies inventory management and drives productivity to new heights.

Benefits of Vertical Lift Modules (VLMs)

Investing in Vertical Lift Modules (VLMs) offers significant benefits for businesses looking to optimize storage space and improve operational efficiency. These automated storage solutions can dramatically reduce floor space requirements by utilizing vertical height, while also enhancing picking accuracy and speed thanks to their advanced software features and intuitive user interface. By streamlining inventory processes and reducing manual handling, companies will see lower labor costs and a quicker return on investment, making VLMs a smart choice for those aiming to boost productivity and profitability.

Understanding Vertical Lift Modules

Vertical Lift Modules (VLMs) are transforming the landscape of warehouse storage and inventory management. These advanced systems shift from traditional “person to goods” approaches to a more efficient “goods to person” model. VLMs are reshaping industrial storage solutions in significant ways.

What are Vertical Lift Modules?

VLMs are automated storage and retrieval systems consisting of two columns of trays with a central lift mechanism. This innovative system allows VLMs to:

- Maximize vertical space utilization, often reaching from floor to ceiling

- Deliver items to operators at accessible heights, enhancing workplace safety

- Provide high-density storage while minimizing floor space requirements

- Offer a controlled environment that protects stored items from dust and damage

How Do Vertical Storage Solutions Work?

The streamlined process behind VLMs eliminates time-consuming searches and reduces the physical strain on workers, significantly boosting operational efficiency:

- Inventory management: Items are stored on trays within the VLMs enclosed structure.

- Retrieval process: When an item is needed, an operator inputs the request into the system.

- Intelligent software:The VLMs software locates the requested item, determining which specific tray and compartment that item has been assigned to.

- Automated movement: The central elevator quickly moves to the tray’s location and retrieves it.

- Ergonomic delivery: The system presents the tray to the operator at a comfortable working height.

- Efficient return: After the operator retrieves the item, the tray is automatically returned to an optimal storage location.

VLM Advantages

Vertical lift modules, tailored to various sizes and needs, offer the ultimate solution for diverse operational requirements.

Amplify Capacity

Support up to 2,200 lbs. per tray with a range of dimensions for every need.

Reinvent Your Space Utilization

Dramatically shrink your storage footprint by up to 90% by utilizing vertical space.

Adaptive Design

Our modular approach ensures limitless adaptability for any storage challenge.

Integrated Control with Modula's WMS

Seamlessly manage inventory or integrate with your existing ERP for straightforward operation.

Growth and Adaptability

Scale effortlessly with your business demands. Expand your ASRS to match your growth trajectory.

Eco-Friendly Solution

Smaller storage areas translate to reduced energy consumption, minimizing waste and enhancing efficiency.

Time-Saving Solutions

Instantly locate necessary parts and products. Increase throughput without additional staffing.

Precision and Accuracy

Simplify picking with intuitive aids, reducing costly errors.

Advanced Inventory Management

Leverage data for inventory insights, reducing paperwork and mistakes.

Effortless Software Integration

Enhance processes with software that dovetails with any ERP. Simplify inventory management.

Access Control

Protect your inventory with controlled access and advanced verification systems.

Future-Ready Investments

Future-proof your operations with a VLM designed for your specific needs.

Ergonomic and Safe

Deliver items at an optimal height for workers, reducing physical strain.

Intuitive and Effective Solutions

Enhance worker satisfaction and effectiveness with computer-aided picking and inventory tracking.

Maximized Productivity

Leap beyond manual system limits with automation.

Prioritize Safety and Comfort

Automate routine tasks, allowing workers to focus on more valuable activities and reducing injury risks.

Redefine Roles

Transform worker responsibilities, reducing time spent navigating the warehouse.

Streamlined Training

Minimal training required. Maintain high productivity levels even with staffing changes or new shift patterns.

Choosing the Right Vertical Lift Module for Your Needs

Selecting the appropriate Vertical Lift Module (VLM) is crucial to maximize your investment. Consider these key factors when choosing a VLM system for your organization:

- Assess Your Storage Needs: Evaluate the types, sizes, quantities, and weights of items you need to store. This will help determine your VLM’s required tray capacity, dimensions, and load-bearing capabilities.

- Consider Space Constraints: Measure your available floor space and ceiling height. VLMs are designed to maximize vertical space, so understanding your spatial limitations is crucial for selecting the right model.

- Analyze Throughput Requirements: Calculate your required retrieval speeds and frequencies. This will influence the choice of VLM model and whether you need multiple access points or bays.

- Evaluate Integration Capabilities: Ensure the VLM’s software integrates with your existing warehouse management system (WMS) or enterprise resource planning (ERP) software for seamless inventory control.

- Understand Your Full Range of Inventory: If you handle both small parts and palletized goods, consider how VLMs can work alongside both traditional systems, like selective pallet rack, and other automated systems, like pallet shuttles, for comprehensive storage solutions.

Have any questions? Contact us to learn more about Modula VLMs.

Technical Features

| UNIT HEIGHTS | from 10’10” (3,300 mm) to 52’10” (16,100 mm) |

|---|---|

| THROUGHPUT | up to 120 trays/hr (depending on configuration) |

| UNIT HEIGHT INCREMENT | 7.87” (200 mm) |

| BAY DELIVERY OPENINGS | 27.36″ H, 35.23″ H & 50.98″ H |

| TRAY WIDTHS | from 59.05” (1,500 mm) to 161.41” (4,100 mm) |

| NUMBER OF BAYS | up to 3, front and rear of the units or on multiple floors |

| TRAY DEPTHS | 25.75” (654 mm), 33.74” (857 mm), & 44.49″ (1,257 mm) |

| TYPES OF BAYS | internal or external, single or dual tray delivery |

| NET TRAY PAYLOAD CAPACITIES | 551 lbs (250 kg), 1,102 lbs (500 kg), 1,653 lbs (750 kg) & 2,182 lbs (990 kg) |

| GROSS TOTAL PAYLOAD | up to 200,000 lbs (90,000 kg) depending on configuration |

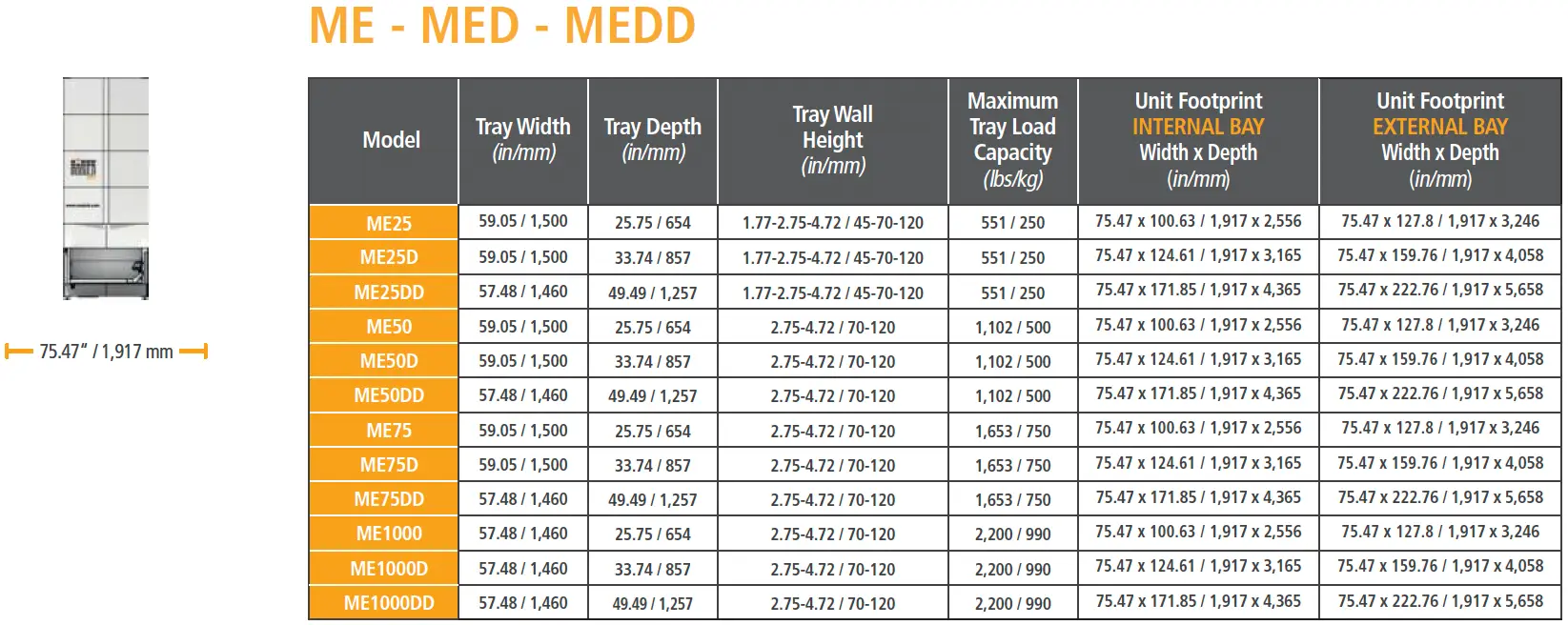

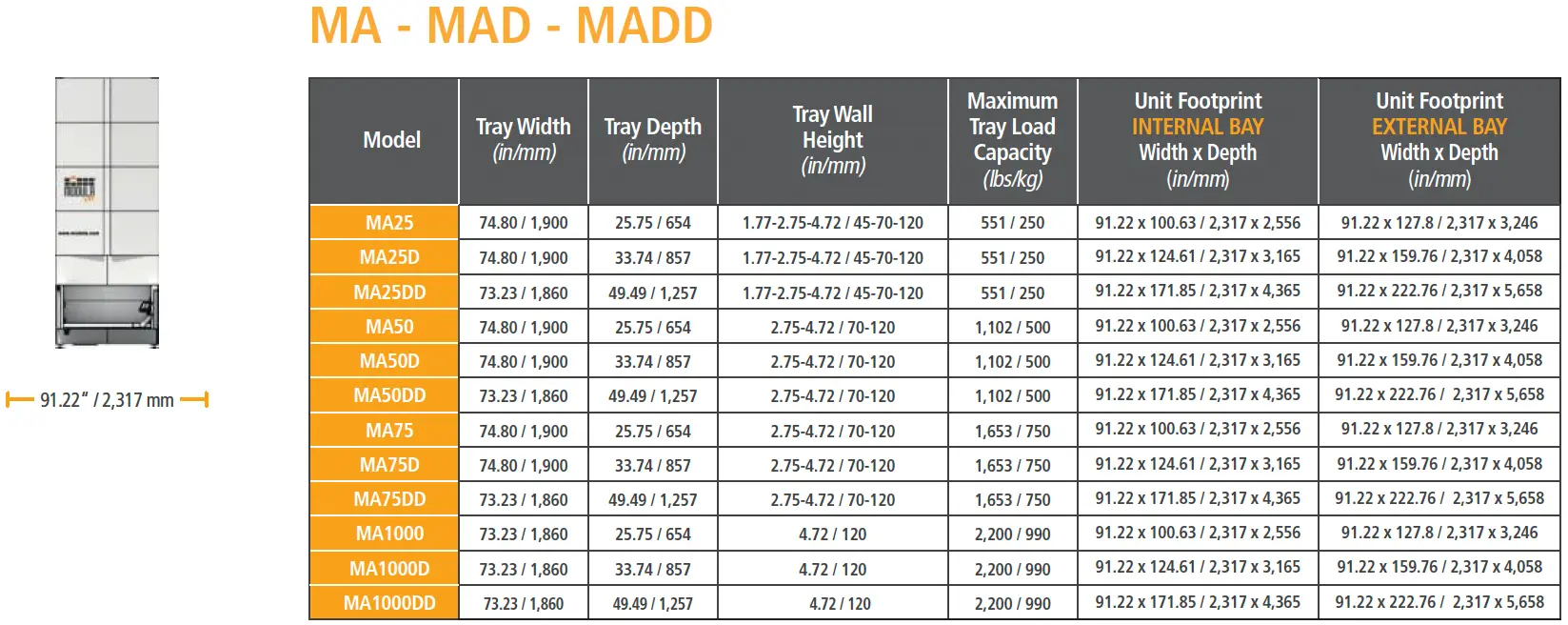

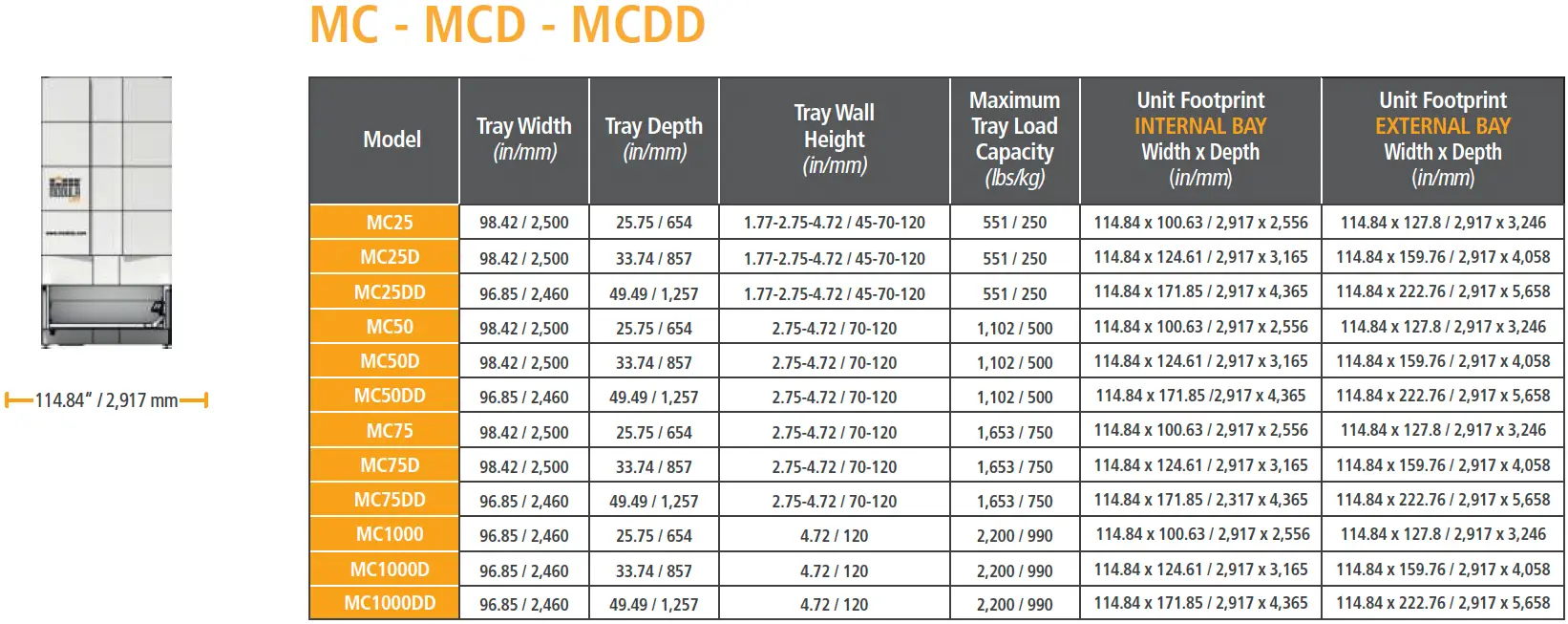

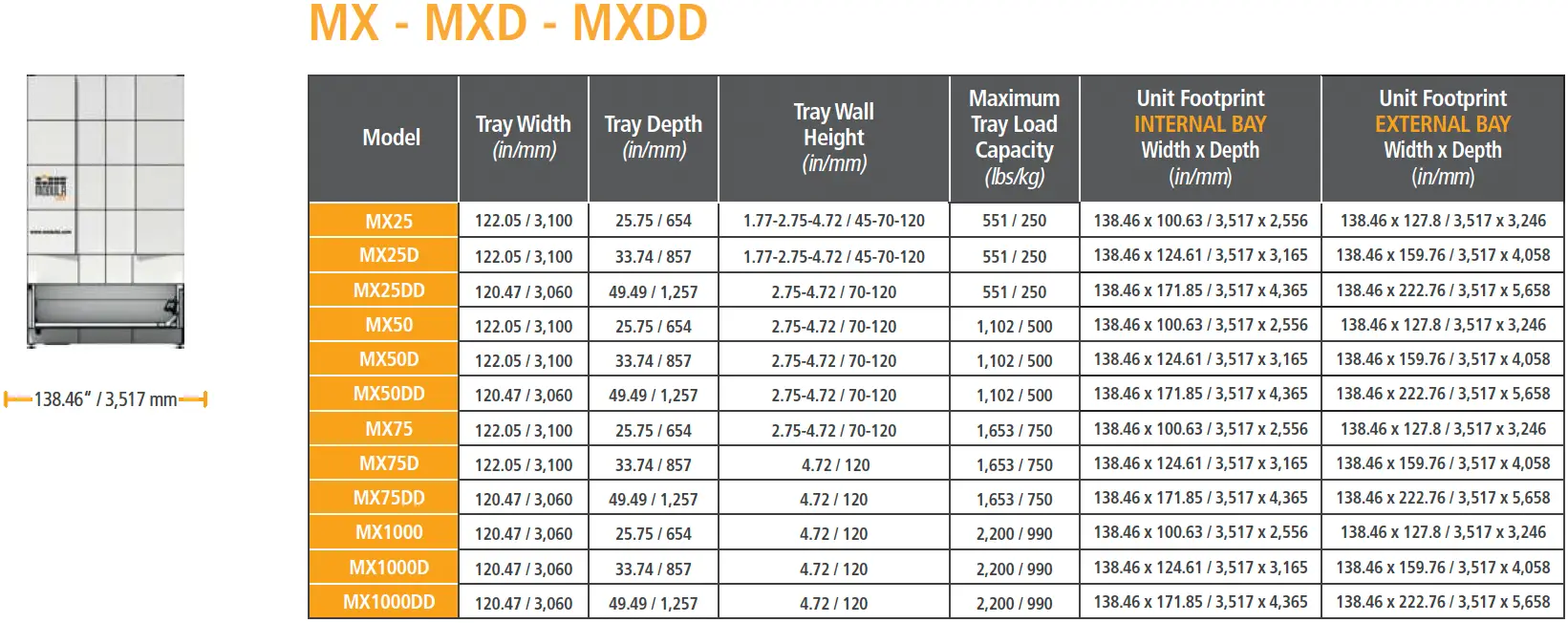

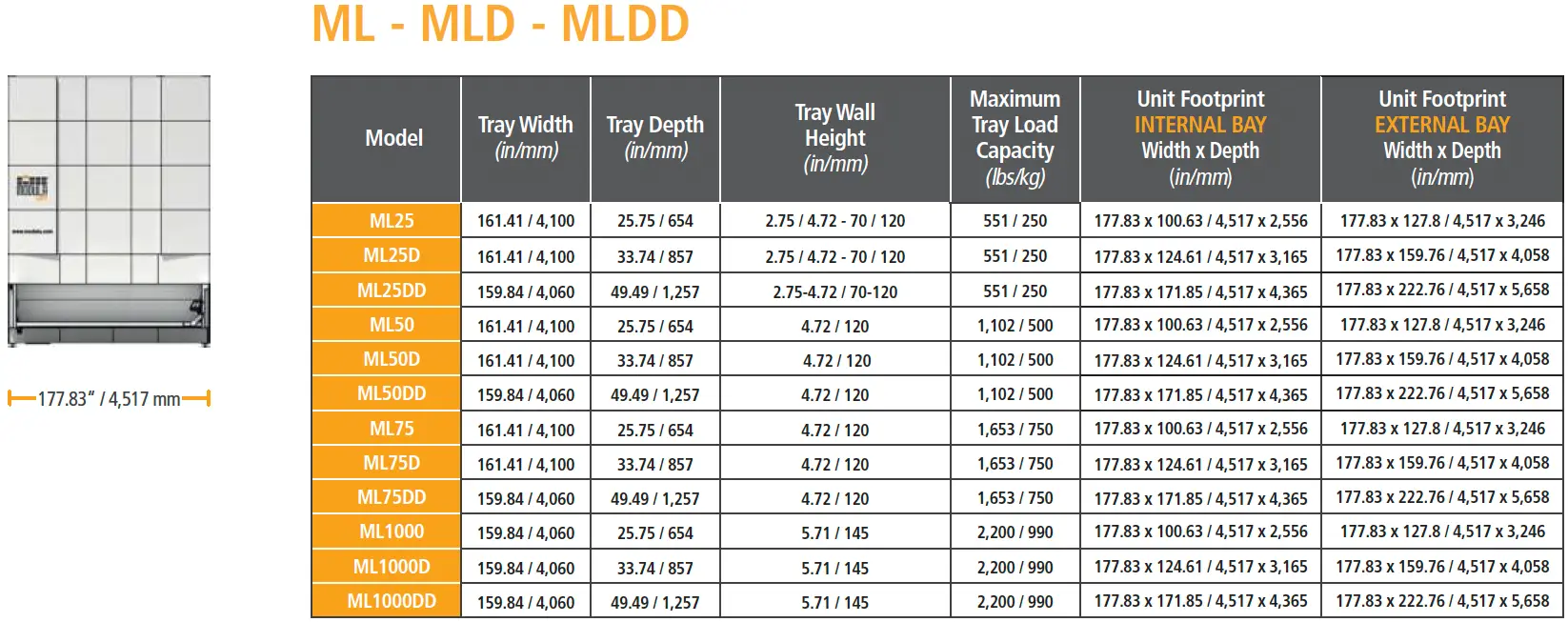

Explore Models

Modula LIFTs come in five different machine widths, and with a host of machine depth and capacity options, there is an ideal machine for every application.

Comprehensive VLM Solutions

Introducing the Prestige Mod Squad

Step into the world of Modula VLMs with the support of Prestige’s Mod Squad, a team equipped for comprehensive installations and attentive maintenance services. Our approach is grounded in delivering meticulous care and support for your vertical storage systems, from the moment of installation through the entire lifecycle of your unit.

While proactive maintenance is central to our service, the reality of operational demands means issues may occasionally arise. Should you need us, the Prestige Mod Squad is prepared to respond with the expertise and efficiency your situation requires. We value the trust you place in our hands, and we stand ready to assist with a practical, skilled approach to service.

Our promise isn’t just about responding rapidly; it’s about providing the right solutions promptly, ensuring that your VLMs maintain a standard of performance that meets your operational needs.