High-density mobile racking and shelving systems are among the most effective tools for optimizing warehouse space without expanding your facility’s footprint. These systems offer innovative ways to eliminate wasted aisle space and enhance storage efficiency. In this article, we explore various types of mobile racking and shelving systems available through Prestige, focusing on the specific use cases where each system excels. Whether you need to manage bulk goods, organize delicate materials, or maximize space efficiency, our high-density solutions offer flexibility and adaptability for diverse industries.

Prestige offers a comprehensive range of high-density mobile storage solutions in partnership with Montel, a leading manufacturer in mobile storage technology. By partnering with Montel, Prestige is able to deliver cutting-edge mobile storage systems that cater to a wide variety of storage requirements. These solutions represent only a part of what we can provide, showcasing a broad set of capabilities designed to suit specific needs.

Prestige provides a variety of advanced mobile storage products, designed to maximize space and improve operational efficiency. Our offerings include but are not limited to: Manual Mobile Shelving, Powered Mobile Shelving, Manual Mobile Racking, and Powered Mobile Racking.

Manual mobile shelving systems are an efficient, budget-friendly option for facilities looking to optimize storage without investing in powered solutions. These systems use hand-operated mechanisms, allowing staff to move shelving units along tracks to access stored items. By consolidating shelves into a compact, movable unit, manual mobile shelving maximizes storage density, making it ideal for small to mid-sized spaces where floor area is at a premium. This option also minimizes wasted aisle space, allowing facilities to store more items in a smaller footprint.

Because manual mobile shelving doesn’t require power, it’s a great choice for businesses looking to save on energy costs while maintaining easy access to their inventory. These systems are versatile and work well for a range of industries, from libraries to parts storage. With straightforward operation and minimal maintenance, manual mobile shelving offers a practical, durable solution for companies that need reliable storage without the need for automation.

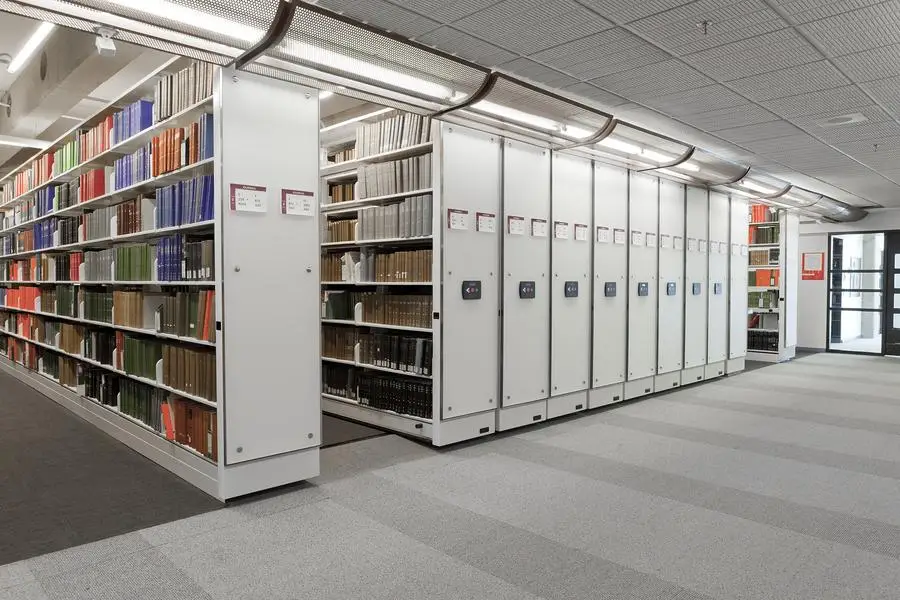

Powered mobile shelving takes the benefits of compact shelving a step further by automating movement. With a simple control panel, users can access specific aisles quickly and efficiently, reducing the physical effort and time needed to locate items. This powered functionality is particularly advantageous in environments with high inventory turnover or frequent retrievals, where quick access to items is essential. Enhanced safety features, such as sensors that stop movement if an obstruction is detected, make powered mobile shelving safe and user-friendly.

Additionally, powered mobile shelving can be configured to meet unique storage requirements, making it adaptable for a wide range of items, from medical supplies to archival records. The system’s automation optimizes space while reducing operational strain, making it ideal for facilities that need to balance high storage density with ease of access.

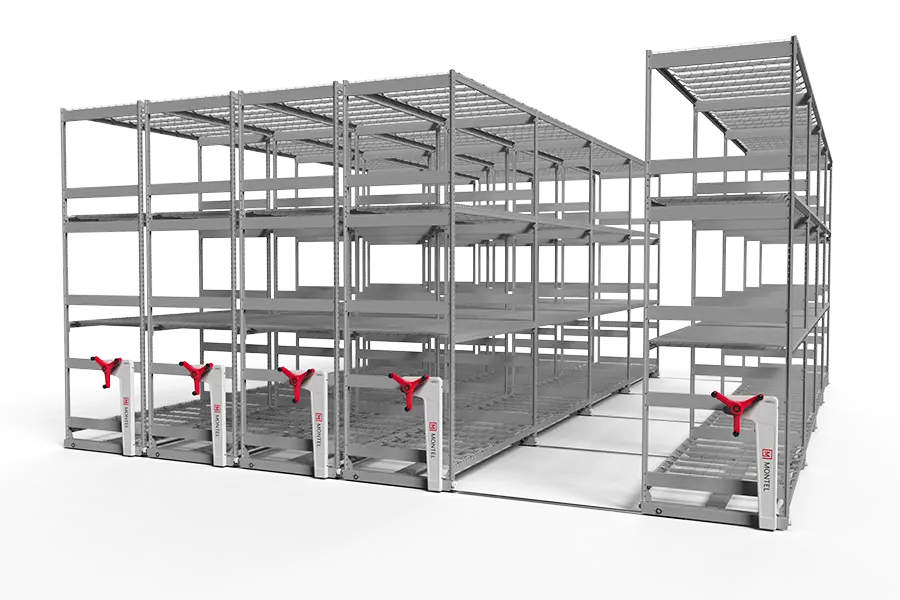

Manual mobile racking offers a practical solution for facilities needing high-capacity storage for lighter-weight pallets without the complexity or cost of powered automated systems. While these racks can be moved manually along tracks, they are generally better suited for lighter loads, making them an ideal choice for environments where heavy-duty capacity isn’t required. By consolidating multiple racks into a shared track system, manual mobile racking reduces aisle space, allowing facilities to increase their storage density efficiently.

This system’s simplicity and durability make it a low-maintenance option, perfect for industries like retail storage or light manufacturing where budget and straightforward operation are priorities. Manual mobile racking provides flexibility without the added features of powered systems, making it an economical solution for businesses that don’t need the extra load capacity or automation.

Powered mobile racking combines the storage capacity of manual systems with the efficiency of automation, offering a premium solution for high-density, high-access environments. This system is particularly beneficial in large warehouses and facilities with high inventory turnover, as the powered movement reduces retrieval times and improves workflow. With automated controls, users can easily shift racks to create an access aisle wherever needed, optimizing both space and time management.

Built-in safety features, such as motion sensors and automated stops, ensure that powered mobile racking operates safely even in high-traffic environments. This racking system is highly adaptable to various storage configurations and is suited for facilities handling heavy goods, cold storage, or temperature-sensitive items, where efficiency and reliability are paramount.

High-density mobile racking and shelving systems come in many forms, each tailored to meet the needs of specific environments and industries. While this article covered several of the most popular systems, these represent only a portion of the options available. Prestige can provide many more solutions, each with unique features suited to specialized use cases. From heavy-duty powered racking systems to small-scale manually driven shelving, Prestige has the expertise to help your business make the most of its storage space.

By understanding the different types of mobile storage solutions and their applications, you can select the right system to optimize your facility’s efficiency and capacity. Prestige offers a comprehensive service, from assessing your needs to installing and maintaining the perfect solution for your business.

Contact us today to learn more about how Prestige can help you implement the right mobile racking or shelving system for your warehouse or facility.

Explore our projects, offerings, and company / industry news

Free shipping is available for online orders shipped to facilities within a 25-mile radius of Chattanooga, TN.