At Prestige, our mission to optimize warehouse storage systems continues with an exciting transformation for a long-time customer, a chemical manufacturer in Tennessee. The initial phase of this project involved disassembling a 3,2000 sq. ft. two-level shelving system (read more about this here), and ultimately was replaced with two Modula Vertical Lift Modules (VLMs). These automated system upgrades significantly enhance storage capabilities, improve space utilization, and streamline operational efficiency.

To see the incredible transformation in action, check out this time-lapse video.

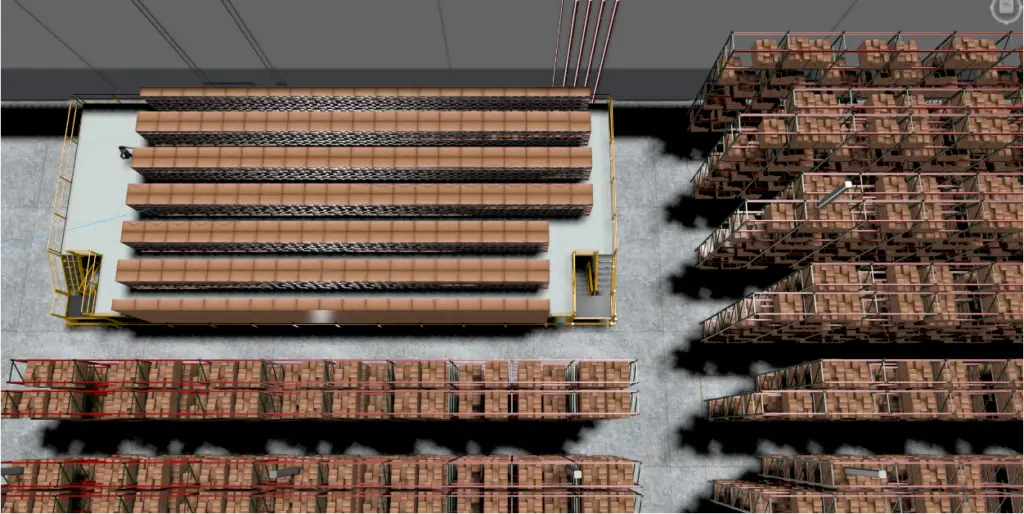

As a recap, the project began with the carful disassembly of an extensive two-level shelving system that spanned 3,200 sq. ft. and included 468 sections. While this shelving setup was functional, it was no longer the most efficient use of space, as the customer was in need of more high-bay racking pallet positions. Prestige’s experienced team meticulously managed the disassembly, ensuring minimal disruption to the customer’s operations. This step was crucial for the seamless installation of the new automated storage solution.

A portion of the two-level shelving system is still available for sale. Please visit our used inventory page or contact us for more information.

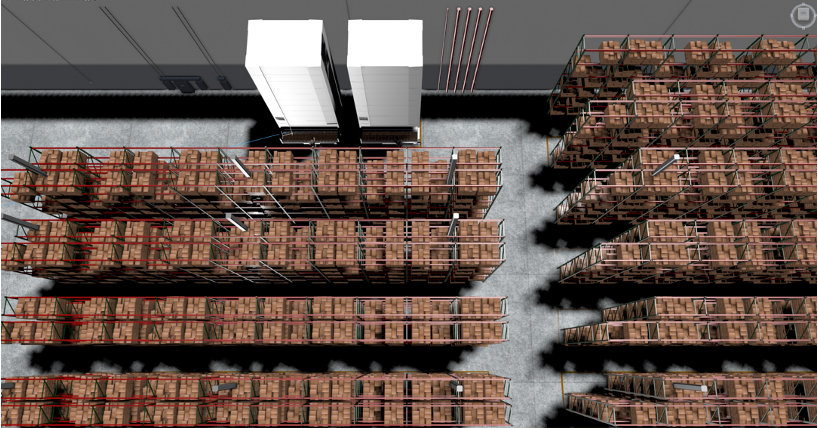

The centerpiece of this transformation was the installation of two Modula Vertical Lift Modules (VLMs). Each VLM stands at 36.5 feet tall and contains 76 trays, each 13 feet wide. These VLMs significantly maximize vertical space, reducing the total utilized footprint to just 480 sq. ft. This represents an 85% reduction in floor space compared to the previous shelving system, allowing the customer to add more high-bay racking, or potentially additional VLMs.

Implementing VLMs has provided the customer with numerous advantages:

The VLMs are now being used to store parts for the factory’s MRO (Maintenance, Repair, and Operations) room, enhancing the efficiency and organization of critical components. This has streamlined the workflow, ensuring that essential parts are readily accessible and well-managed.

Transforming the warehouse shelving system to a semi-automated setup marks a significant milestone in our customer’s journey towards greater efficiency and productivity. The installation of the Modula VLMs has saved valuable floor space and brought numerous operational benefits. At Prestige, we are committed to delivering customized automated storage solutions that drive real value for our customers.

For more information about how Prestige can help transform your warehouse with both automated and traditional storage solutions, please contact us today. We look forward to partnering with you to create innovative and efficient storage solutions tailored to your specific needs.

Ready to optimize your warehouse with automated storage solutions? Contact Prestige today to learn more about our Vertical Lift Modules and how they can transform your storage capabilities. Get in touch now to start your journey towards enhanced efficiency and productivity.

Q: What is a Vertical Lift Module (VLM)?

A: VLMs significantly reduce the floor space needed compared to traditional storage systems by maximizing vertical storage capacity. Some customers see up to 90% space savings.

Q: How much floor space can VLMs save?

A: VLMs significantly reduce the floor space needed compared to traditional shelving systems by maximizing vertical storage capacity.

Q: What types of items can be stored in VLMs?

A: VLMs can store a wide range of items, including parts for manufacturing, maintenance, repair/operations (MRO) components, tools, and various other inventoried products.

Q: How do VLMs improve inventory management?

A: VLMs provide real-time data on stock levels and movements, enhancing accuracy and facilitating better decision-making and planning. Click Here to Learn more about the software capabilities of a Modula VLM.

Q: Are VLMs secure?

A: Yes, VLMs come with advanced security features to protect valuable inventory, ensuring that only authorized personnel have access.

Q: Can VLMs handle heavy and bulky items?

A: Yes, VLMs are designed to handle a wide range of item sizes and weights, making them ideal for storing heavy and bulky items. There are options for tray capacities ranging from 551 lbs. to 2,200 lbs.

Q: Are VLMs energy efficient?

A: VLMs are energy efficient, designed to reduce energy consumption and operational costs while enhancing productivity.

Q: What industries can benefit from VLMs?

A: The beauty in a VLM is that they are industry agnostic. Customers leverage this vertical technology from Aerospace to Agricultural to Medical and everything in between

Q: Is the old shelving system available for sale?

A: Yes, a portion of the two-level shelving system is still available for sale. Please visit our used inventory page or contact us for more information.

Explore our projects, offerings, and company / industry news

Free shipping is available for online orders shipped to facilities within a 25-mile radius of Chattanooga, TN.