-

ABOUT

-

In the ever-evolving world of storage and material handling, Prestige continually demonstrates its commitment to innovation and efficiency. Our recent project showcases not only our adaptability in the face of unexpected challenges but also our expertise in optimizing warehouse spaces with mezzanines, pallet racking systems, automated systems, and more.

One of Prestige’s longest-time customers approached us in 2020 to maximize storage in a new expansion. While the original plan was to design a three-level traditional mezzanine that housed static rivet rack and shelving, the onset of the COVID-19 pandemic brought these plans to a halt, relegating the building to ground-level storage use.

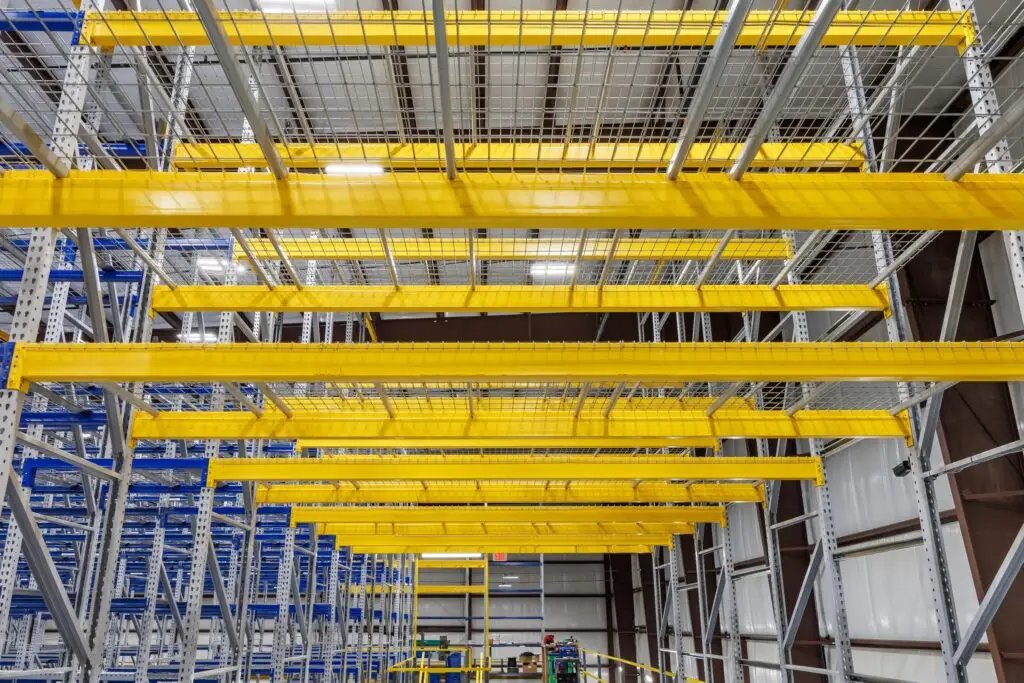

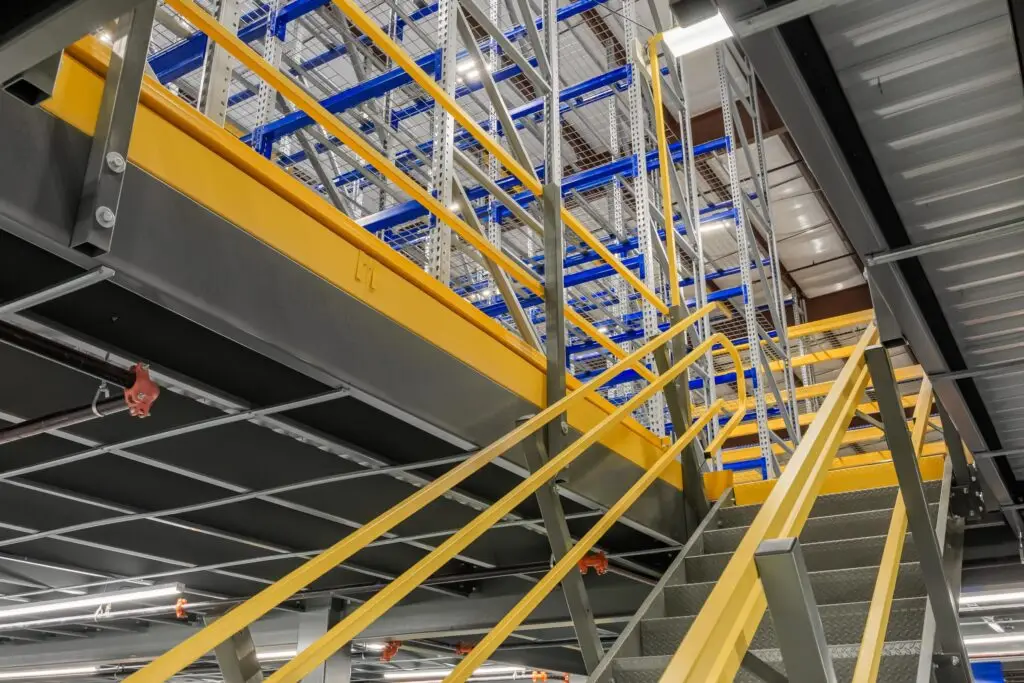

In 2021, discussions resumed, but the pandemic’s impact on operations led the customer, Prestige, and other partners to reconsider the approach. The project evolved to focus on a more dynamic solution. After extensive evaluations of static, semi-automated, and fully automated systems, a decision was made. The optimal solution? A two-level structural mezzanine with a shelf-to-person storage and picking system, integrated with fully automated sortation. This choice was driven by both current needs and future projections.

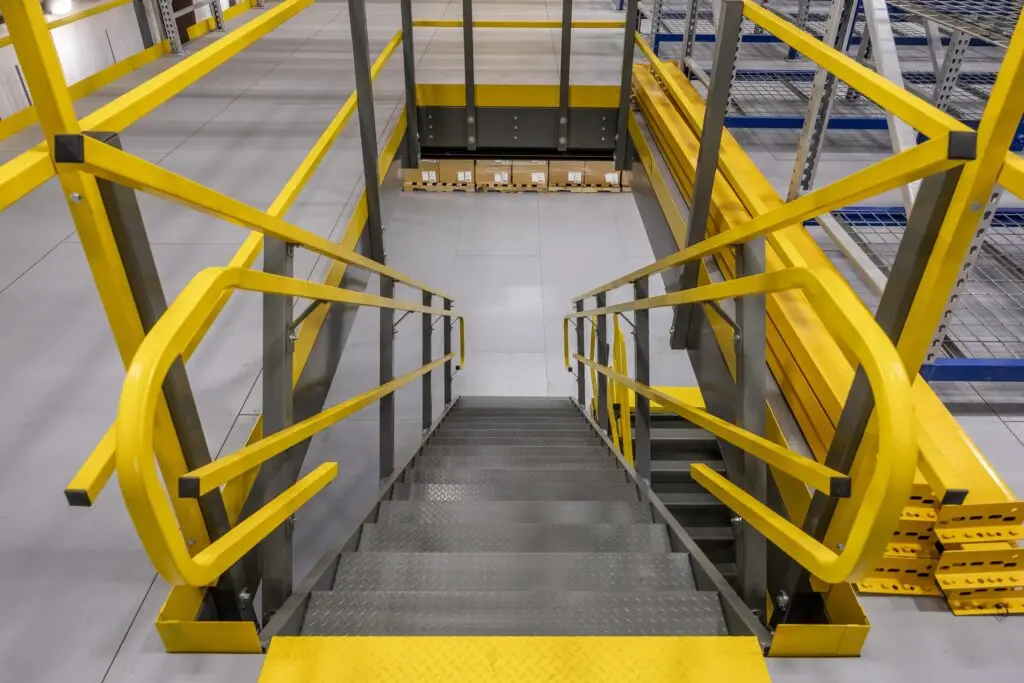

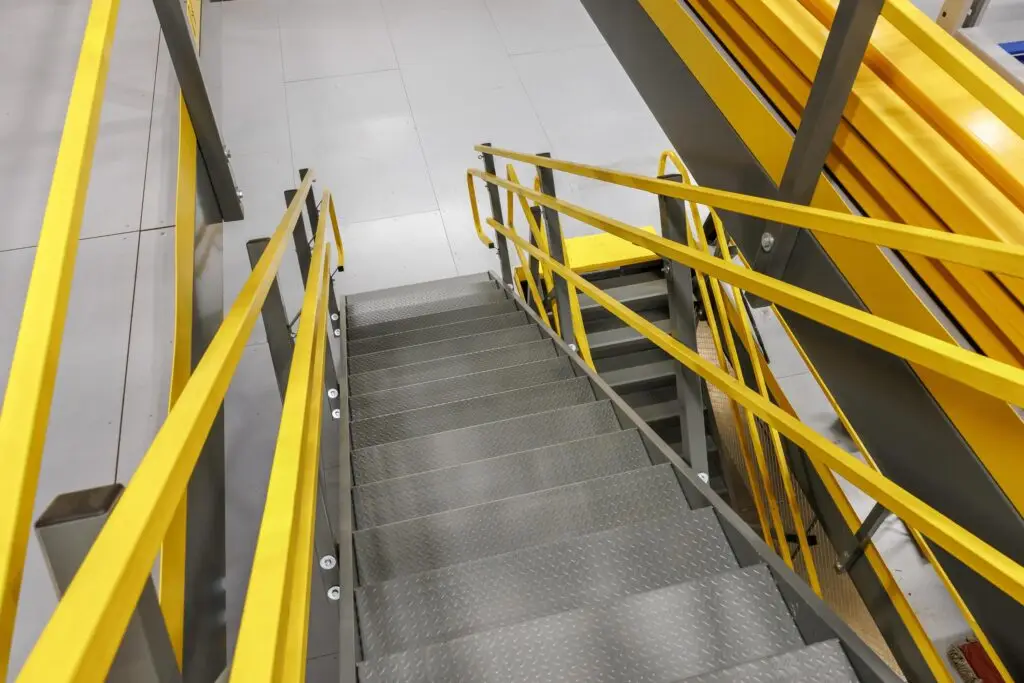

Key to this project was the design and installation of a multi-level mezzanine, making full use of the building’s 45’ clearance. This two-level structural mezzanine, manufactured by Wildeck and measuring 87’ D x 307’ W, provided an impressive 53,418 Sq Ft of additional space.

The mezzanine levels are seamlessly connected through spiral vertical rise conveyors and powered accumulation roller conveyors, enabling effortless movement of products across all levels.

This project not only highlights Prestige’s ability to adapt and innovate in challenging circumstances but also our expertise in creating efficient, space-optimized storage solutions. By embracing advanced technologies and custom-engineered mezzanines, a conventional warehouse has been transformed into a state-of-the-art storage and picking facility.

Prestige continues to redefine warehouse optimization and space transformation, ensuring that our solutions not only meet current demands but are also poised for future challenges and opportunities.

Contact us today for more information on our storage solutions and to see how we can transform your warehouse space.

Q: What is a mezzanine, and why is it useful for warehouse optimization?

A: A mezzanine is an intermediate floor or platform installed between the main floors of a building, typically used in warehouses to maximize usable space. It’s highly beneficial for warehouse optimization as it effectively doubles or even triples the available storage or operational area without the need for expanding the building’s footprint. This makes mezzanines a cost-effective solution for increasing storage capacity, improving organization, and enhancing operational efficiency in warehouse environments.

Q: How does the Multi-Level Mezzanine enhance warehouse efficiency?

A: By adding vertical storage space and integrating automated systems, the mezzanine increases storage capacity and streamlines picking and sorting processes.

Q: Can the mezzanine structure be adapted to different warehouse sizes?

A: Absolutely. The modular design allows for customization to fit various warehouse dimensions and storage requirements.

Q: What safety measures are incorporated into the design?

A: The entire system is engineered with seismic considerations and the selective racking includes overhead cross-ties for stability, ensuring a safe environment for warehouse operations.

Q: How does the design of the Multi-level Mezzanine support different types of storage systems?

A: The Multi-Level Mezzanine is engineered to accommodate a variety of systems, from manual to fully automated solutions. Its versatile design allows for easy integration with different types of racking, shelving, and conveyor configurations, catering to diverse storage and retrieval needs. This flexibility ensures that the mezzanine can be utilized in various operations and processes, enhancing overall warehouse functionality and efficiency.

Explore our projects, offerings, and company / industry news

Prestige is an assumed name of Prestige Sales Company, Inc. All references to Prestige shall be deemed to refer to Prestige Sales Company, Inc.

Free shipping is available for online orders shipped to facilities within a 25-mile radius of Chattanooga, TN.